The company

Laboratory

Conveyor Belt Structure

Downloads

Handling

Contact

- Steel Cord conveyor belts

- Multy Ply conveyor belts

- Mono Ply conveyor belts

- Anti-Abrasion conveyor belts

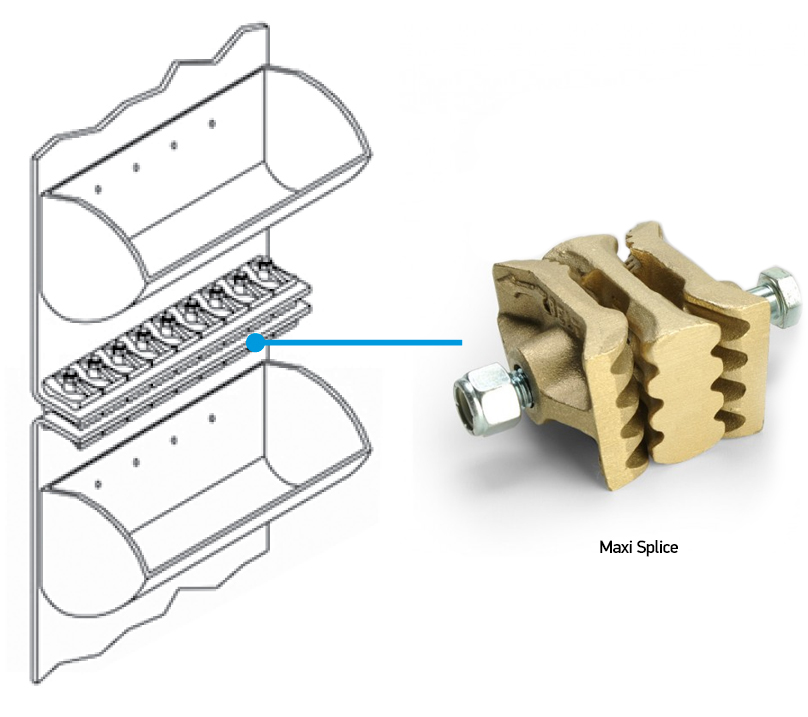

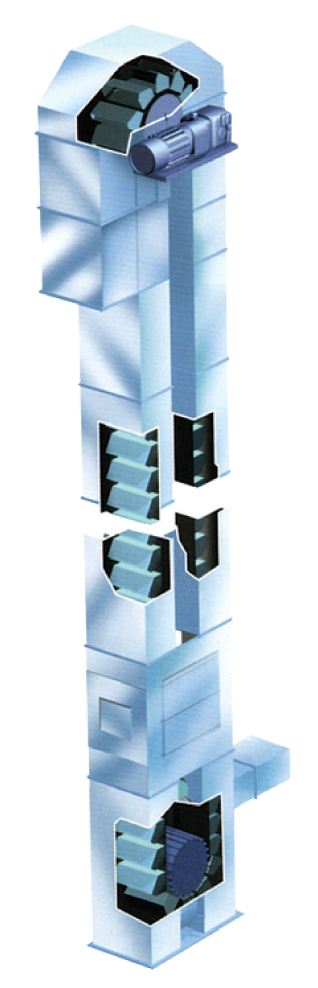

- Elevators belts

- RIP Protection conveyor belts

- Food Industry conveyor belts

- Side Wall conveyor belts

- Pipe conveyor belts

- Heat, Oil and Fire Resistant conveyor belts

- Grain Handling Conveyor Belts

- Chevron conveyor belts

- Patterns conveyor belts

The company

Laboratory

Conveyor Belt Structure

Downloads

Handling

Contact

- Steel Cord conveyor belts

- Multy Ply conveyor belts

- Mono Ply conveyor belts

- Anti-Abrasion conveyor belts

- Elevators belts

- RIP Protection conveyor belts

- Food Industry conveyor belts

- Side Wall conveyor belts

- Pipe conveyor belts

- Heat, Oil and Fire Resistant conveyor belts

- Grain Handling Conveyor Belts

- Chevron conveyor belts

- Patterns conveyor belts